- Our Company

- All India Associates

- Youtube

- Career

- Industry Sector We Serve

-

Electronic Products

- Digital / CAT Tacho Hour Meters

- Digital RPM / Hour Indicators (With LCD / LED Display / Programmable)

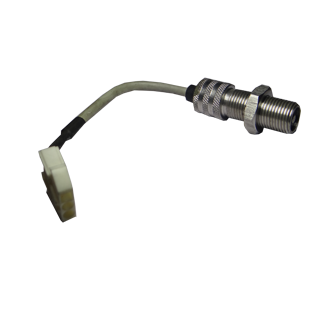

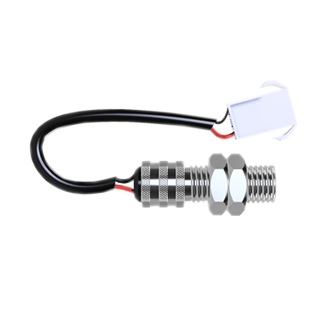

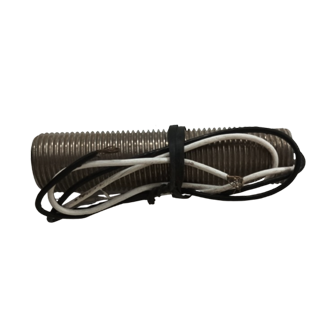

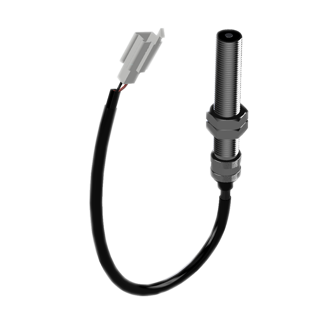

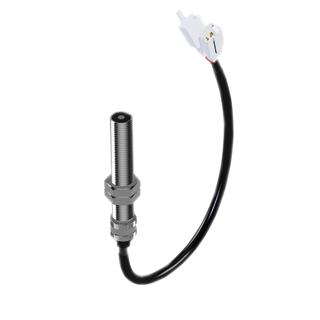

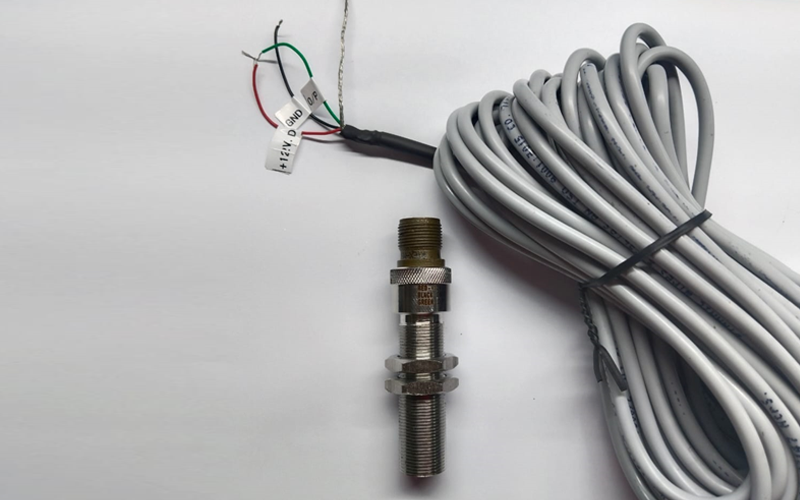

- Magnetic Speed Sensors (Magnetic Pickups)

- Import Substitute MPU (Magnetic Pickups / Magnetic Speed Sensors)

- Hall Effect Speed Sensors, Unidirectional / Bidirectional Speed Sensors

- Digital Hour Meters

- Digital Speedometers For Tractors, Agricultural Machines

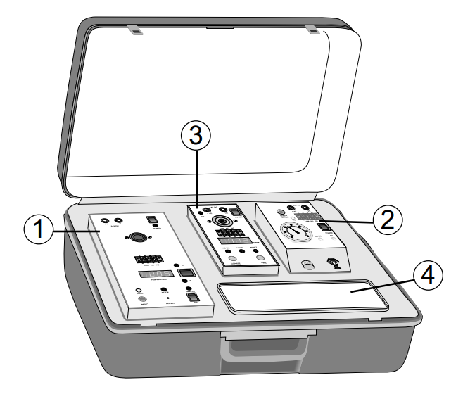

- Safety Control Test Rig Kits For Marine, Diesel Engine Commissioning

- Electronic System Engineering Services

- Testimonials

- Event & Achivemets

- News & Media Coverage

- Contact Us